Managing Key Cores with Reduced Shipping and Storage Costs

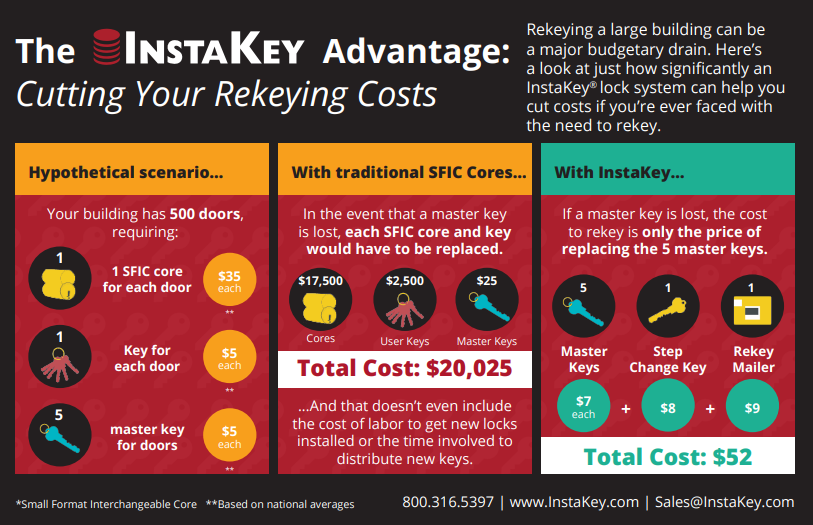

When a key is lost or stolen, there can be seemingly no limit to the number of affected locks that require changing or rekeying.

The benefits of eliminating locksmith callouts for such a scenario are well documented. As a facilities manager, you may or may not have the budget to spend on outsourcing this grueling, crucial work. You almost certainly do not have the time.

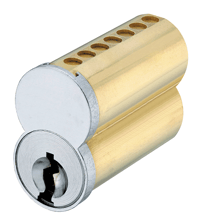

That’s what makes core swap programs so enticing. As an alternative to calling a locksmith, utilizing a system of keys + cores, sometimes referred to as key cores (small format interchangeable cores or SFIC) can be both cheaper and faster. There’s no need to hire — and subsequently wait on — another person to do the job for you. It puts you (or your maintenance staff) directly in control of the situation.

Here’s how it works: When a lock is compromised, rather than replacing the hardware entirely, you merely swap out the core. The more cores you have on site, the more lock-and-key options you have available to you. The best part — the lock hardware/housing itself never has to leave the door.

But a core swap program is not without its downsides. You never want to feel as if you’re trading one headache for another that is equally painful (if not more so). But with the way core swap programs traditionally work, that unfortunately may be the case from a procurement, delayed shipping, order tracking, order accuracy and key management perspective.

Here’s a look at some of the issues, as well as suggestions to make your key control program even better. With these tips, it can be efficient but not expensive, and more secure than ever.

The Core Swap Procurement Process

Often times the biggest headache of a core swap program can be managing inventory and creating the orders to match up keys to core sets. Each company is slightly different, but they all have the common headache of paperwork that feels like jumping through unnecessary hoops. Whether you are a purchase order or invoice-based company, the more orders you have to place for core swaps, the less time you have for the rest of your job.

Don't even get us started on the time that is needed when an order is delayed or arrives inaccurate.

Paying for Shipping is Never Fun

If you’re relying on key cores, you’re going to be dealing with a lot of inventory.

If you’re relying on key cores, you’re going to be dealing with a lot of inventory.

At the sound of this, your head may fill up with images of infinite piles of keys and cores on the ground, as you sit in a confused heap trying to sort everything out and match everything up.

While we’re exaggerating (only slightly), that nightmare is one of inconvenience. The factor that’s perhaps more important to consider — especially for management — is cost.

Before those keys and cores arrive at your facility, you have to purchase them. Hopefully you get a deal for buying in bulk. But even if you do, that comes with a drawback of its own: The bigger the order, the more expensive the shipping. And the more shipments you have, the more those costs multiply.

In a way, you’re again merely paying — in time and money — to outsource the job. You may be saving on labor, as you’re replacing the key cores yourself. But you’re still spending a pretty penny on product and often your shipping wait times are two to four weeks, which could also be costing you labor time as staff sit and wait for delivery. The other option is to pay for overnight expedited fees, costing hundreds of dollars.

And any money that comes out of your facilities management budget means that other things, maybe more important things, can no longer be afforded.

Where Are You Going to Put All Those Key Cores?

Once the key cores arrive, you have a new problem on your hands. You need to find a place to store everything.

There may be some facilities with ample unused space. But they are absolutely the exception, not the rule.

Rent is expensive and every square foot counts. The fact of the matter is, even if you stash your keys and cores in a small room, that’s another valuable space lost to storage. And we’re willing to bet you or your organization could come up with a better use for that space.

As the facilities manager, you may even be the one to sacrifice some of your domain to house key cores. Not only is your list of concerns expanding, your room to move around and breathe is contracting.

That’s in addition to the money spent on shipping, already taking a significant bite out of your budget.

Getting Key Cores When You Need Them and at a Lower Cost is a Reality

We partner with industry suppliers to fulfill orders on almost any SFIC core on the market today. By partnering with other major manufacturers of non-restricted keys and small format interchangeable cores (SFIC) to provide you with the cores you already use, we can keep costs down, and get you the product you need faster. You don't have time to wait a few weeks to get your order. InstaKey can get your order delivered within 48 hours or less, in most cases.

Struggling to Keep Track of Who Has What Keys?

Before you install new key cores for your key system, you should know that you could be reaping the benefits ofa cloud-based databasethat allows managers to quickly retrieve information on key custody, key system hierarchy, door access relationships, order history and cost analysis reporting that works with any manufacturer's hardware. All you need are unique identifiers on the keys to use one platform for everything key control and solve for one of the downsides of core swap programs.

Is There a Better Way to Manage Key Cores?

After reading all of this you’re probably hoping this post can offer you some help. Fortunately, there is help and you have options, including one that features all the benefits of a core swap program, without the downsides.

IC cores have become a standard in commercial security because you don’t actually have to take the hardware off of the door. But, imagine if you didn’t even have to take the core out to change a lock.

That’s how InstaKey's proprietary rekeyable cores work. The genius design of these IC cores allow you to restore security with one simple rotation of a Step Change Key, something you can do a total of nine times before swapping out the core. You don’t need to get down on your knees to swap out hardware. You don’t even need tools.

InstaKey doesn’t require your organization to spend a fortune on shipping every time you rekey. It doesn’t take up significant physical space in your facility. Rekey kits include the Step Change Key and a new set of keys to distribute to key holders. This small package can be neatly kept on-site, securely in a safe. It doesn't require you to hire an employee dedicated to managing order accuracy or shipment tracking of replacement hardware, nor does it take up much of your precious time.

It comes as close to “set it and forget it” as is humanly possible, turning key control and building security into one less thing for you to worry about. Contact us to learn more about eliminating core swaps and taking control of your key management system.